Table of Contents

What separates SGS™ from our competitors?

To our knowledge, SGS™ shaft grounding systems were the first patented shaft grounding systems available on the market to address the issue of electrical bearing damage on VFD motors. The original patent number is 5,661,356. Beginning out of the Pulp & Paper industry in the 1980s, we have developed an extensive knowledge base that is field tested on shaft grounding system applications over many industries.

What is one significant difference between SGS™ and other leading shaft grounding competitors?

Our patented and proprietary systems are designed to withstand severe industrial environments as well as environments sensitive to emissions. Our competitors use much of the same technology office printers use for grounding static electricity from printer paper. Longitudinal trials of this “fiber-to-shaft” design is only marginally effective for vastly shorter times at decreasing shaft voltages than when compared to SGS™ products.

How long can SGS™ systems run prior to maintenance?

Our CR and SR Series models have proven to run for over 10 years or 100,000 hours of continuous operation (1800rpm) prior to needing an inexpensive brush replacement. Maintenance can usually be done on the fly with our non-drive end shaft grounding systems and is a feature not found in any other shaft grounding device.

Competitors state that spring loaded brush designs apply too much pressure and therefore wear out quickly. True?

While that can be true for other brush-based shaft grounding devices, our SGS™ brush, rotor and ring designs have proven to run as long as 100,000 hours at 1800 rpm prior to needing brush replacement. In addition, lab and field studies have shown the brush effectiveness lasts for the entire wear rate life of the brush. That is to say, voltages are maintained well below the threshold leading to capacitive discharge through the bearing for the entire life of the brush. The brush and the material the brush rides on work together in concert to maintain a clean path for current to flow and SGS™ has figured out how best to make that happen.

Is there potential for shaft damage while running SGS™ shaft grounding systems?

Shaft wear is certainly a valid concern with most shaft grounding systems, however, SGS™ patented brush designs do not cause shaft wear as their wearable points do not contact the shaft. In addition, there is no need to coat the shaft with colloidal silver shaft coating SGS™ CR Series model brush wear after nearly 5 years of continuous run time. Plenty of brush left. Copyright © 2025 DP&A Sales www.shaftgrounding.com material to promote conductivity. All SGS™ products rely on very stable mechanical connections that do not require maintenance and are not negatively impacted by the environment over time. The SGS™ components the brush contacts are so robustly built that they do not require maintenance within the service life of any motor. In fact, SGS™ systems have resided on motors that have been rebuilt several times and so we have made available a simple rebuild kit (CR Series) that will make the system brand-new for a fraction of the cost of a new system. SGS™ ring style systems (drive end) are so robustly built that we have yet to replace a ring in nearly 40 years. A typical micro-filament grounding system weighs less than a pound. A typical SGS™ ring system weighs around 8 pounds.

Do oils and other contaminants negatively affect how well SGS™ shaft grounding systems perform?

No. Our patented and proprietary designs always ensure a clean running surface for the brush to run on. This is a critical differentiation as any grounding system needs to be the best competitor to the bearing for path of least resistance around the bearing and back to the motor frame. A system design that ensures a clean running surface must be achieved. To our knowledge, SGS™ is the only shaft grounding system that achieves and maintains for the long-term a clean running surface ensuring a path of least resistance for current to flow away from the bearing.

When using SGS™, do brush particulates affect the ability of the shaft grounding system to properly ground?

No. We have developed a line of products for use in the clean room industry (CR Series). Extensive customer studies have proven that our patented sealed SGS™ shaft grounding systems can operate in a clean room environment and continue to be effective at shaft grounding while not emitting significant contaminants into the environment at continuous operation at 1800 rpm. It’s that feature that has translated to handling well challenging environmental situations.

Can SGS™ shaft grounding systems operate over a shaft keyway?

Yes. If a non-drive end SGS™ system will not serve your needs, then our SR Series split ring shaft grounding system will operate over a shaft keyway without the time consuming process of filling the shaft keyway with epoxy, etc. If the key impedes on axial shaft space, then SGS™ will accommodate the key.

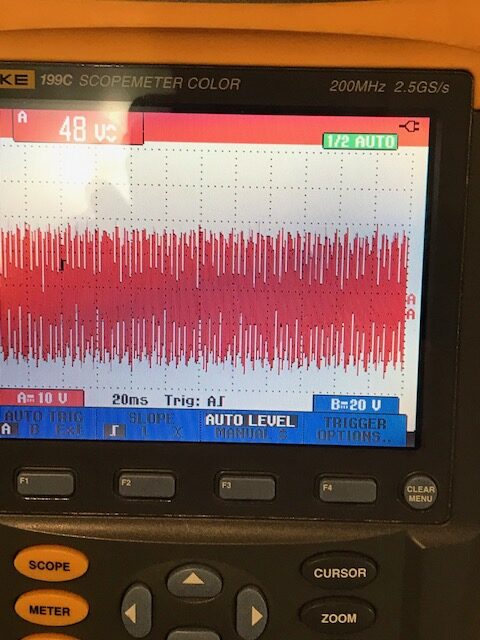

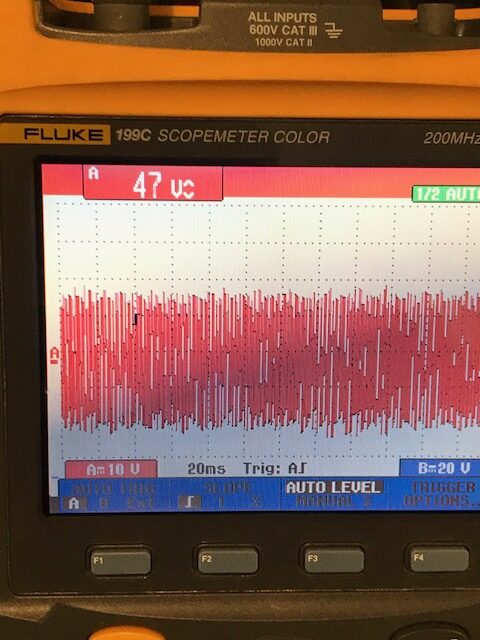

Are inductions absorbers effective at keeping shaft voltages below the threshold needed to prevent capacitive discharge through the bearing?

In short, no. Our field experience and lab studies have shown that induction absorbers can decrease peak voltages the motor experiences and can prevent first turn burnouts, however, they cannot decrease shaft-to-frame voltages to the level that prevents capacitive discharge through the bearing. At best, these products only marginally slow down the effects of capacitive discharge through the bearing.

Is an internally mounted shaft grounding system superior to a shaft grounding system installed externally?

Internally mounted shaft grounding systems do benefit from being less prone to environmental contamination. However, a field analysis of this mounting arrangement has proven that keeping open a path of least resistance is only marginally improved. Of note, these systems had to move internally to the motor due to very poor external performance. In addition, internally mounted grounding systems are not maintainable. Once their grounding performance has waned (likely due to poor wear tolerance), the motor is no longer protected and electrically induced bearing failure can occur. Replacing an internally mounted shaft grounding system is a very costly process.

How does SGS™ product support compare to other brands?

We continue to support originally installed SGS™ products from as long ago as 25+ years. Nobody else provides that level of support. Our clients can call one phone number to get support and we can typically have parts shipped within 1 business day to anywhere in the United States. International shipments also have a quick turn around time.

What is the most important consideration when researching a motor shaft grounding product?

Does the product provide and maintain a long-term path of least resistance for current to flow around the bearing and back to the motor frame? Electricity is simple in that it always travels via the path of least resistance. Surface contamination and poor grounding device wear tolerance are the most common contributors to a failing shaft grounding device. As soon as the grounding system’s path of least resistance is compromised, current will find an alternative path which will be from the shaft through the bearing and leading to electrically induced bearing failure.