Stop Motor Failures Before They Start

Protect your motors for decades—not just the warranty.

SGS™ shaft grounding systems prevent electrically induced bearing damage, keeping your operation running without costly surprises. Trusted worldwide for over 40 years by industries that can’t afford downtime.

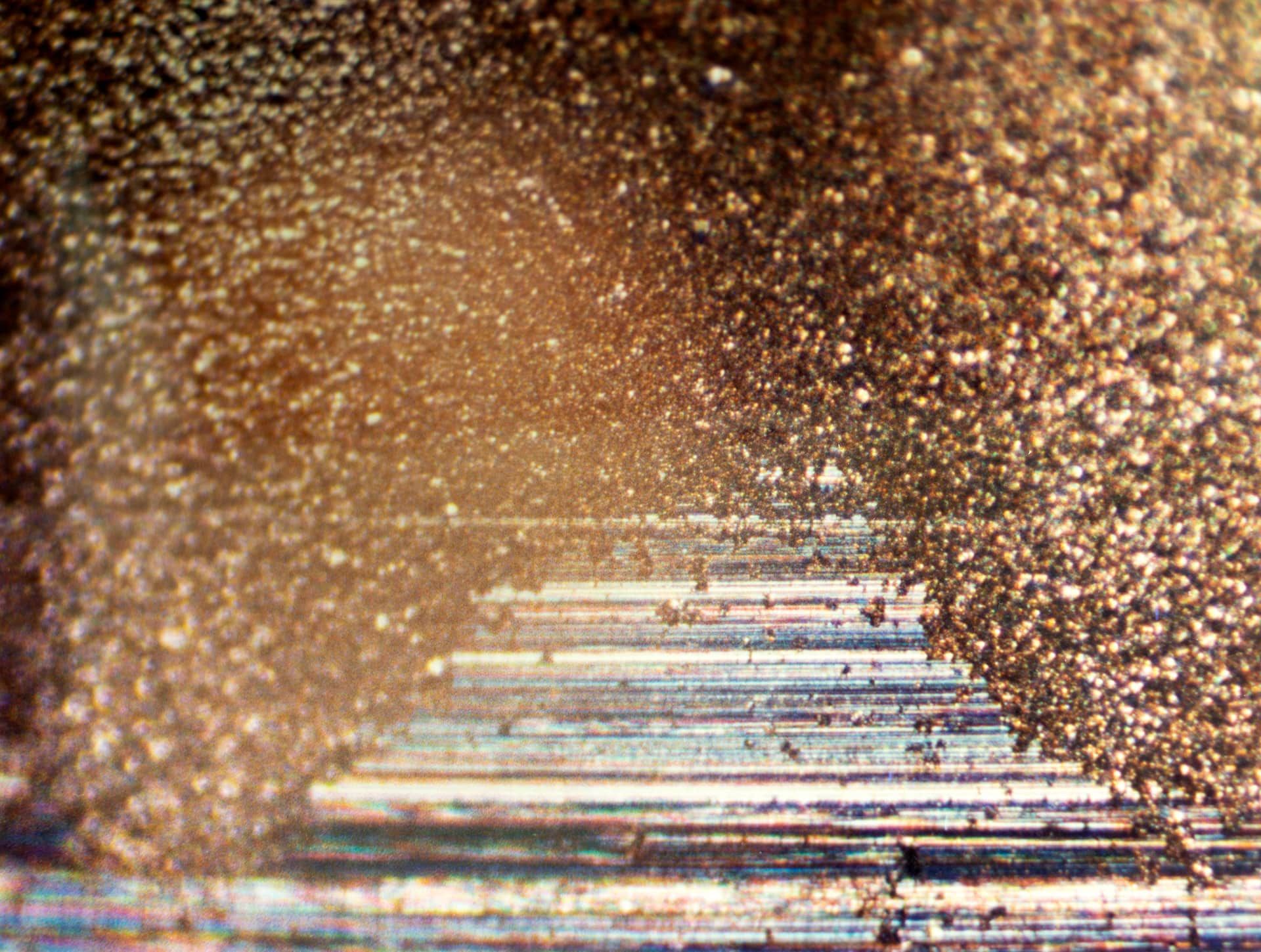

Electrical discharge through bearings silently destroys motors every day.

When VFDs are installed, shaft voltage can arc through bearings—leading to catastrophic failure, expensive repairs, and unexpected downtime.

You may have tried other grounding systems, but most don’t last. They wear out, fail in harsh environments, or require constant maintenance. Meanwhile, the pressure is on you to keep critical systems online.

We Understand the Cost of Downtime

For over 40 years, SGS™ has helped facilities like data centers, hospitals, and manufacturers protect their motors from failure. We design grounding systems that work in the real world—not just on paper—so you can focus on running your operation instead of fixing motors.

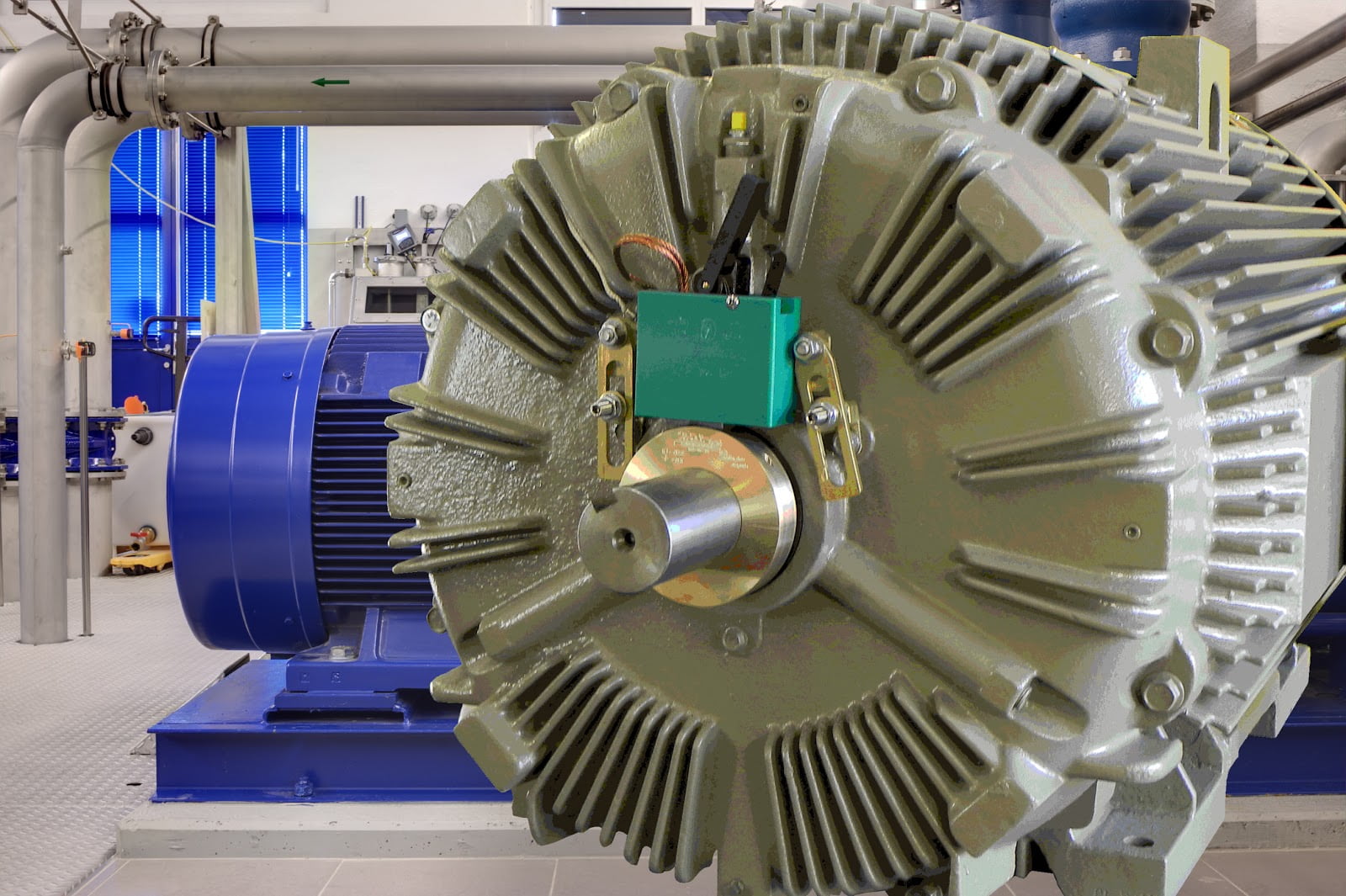

Trusted by Industries That Can’t Afford Downtime

SGS™ is the go-to shaft grounding solution for operations where failure is not an option:

Data Centers • Semiconductor Manufacturers • Major Hospitals • Water Utilities • Paper Mills • Airports • Universities • Food Processing Facilities

Decades of Success, Backed by Real Results

Customers in critical industries have depended on SGS™ for over 40 years.

[Person's Name] testimonial

Since 2005 we have not had one bearing failure due to fluting.

We have 1000s of motors and VFDs on [our] campus and are constantly fighting the effects of motor bearing fluting and subsequent failures from stray shaft voltages. One of our buildings that was commissioned in 2005 contains approximately 20 pieces of original VFD driven motors equipped with the SGS CR series shaft ground[ing]. Since the commissioning in 2005 we have not had one bearing failure due to fluting. I believe this is a testament to the good design of the SGS CR shaft ground. Comparatively, in many of our newer buildings we have several types of shaft grounding, grounding/bonding straps, and electrical chokes installed on VFDs and motors that are claimed to inhibit bearing fluting. The reliability has been sporadic and in many instances poor with these compared to the SGS CR shaft ground[ing] in our 2005 building. This is a great example of a comparative long-term test of what works and what doesn’t.

Protect Your Motors in Three Simple Steps

Designed to fit your operation, our process is quick, clear, and built around your needs.

Share Your Motor Specs

Send us your motor details or a quick inquiry.

Receive Your Custom Quote

We’ll send drawings and documentation tailored to your application.

Install and Relax

Enjoy years of maintenance-free operation—backed by our ongoing support.

The Difference is Measurable

See how SGS™ protects motors compared to systems without it.

Without SGS

- Bearings fail prematurely

- Downtime disrupts operations

- Repair and replacement costs pile up

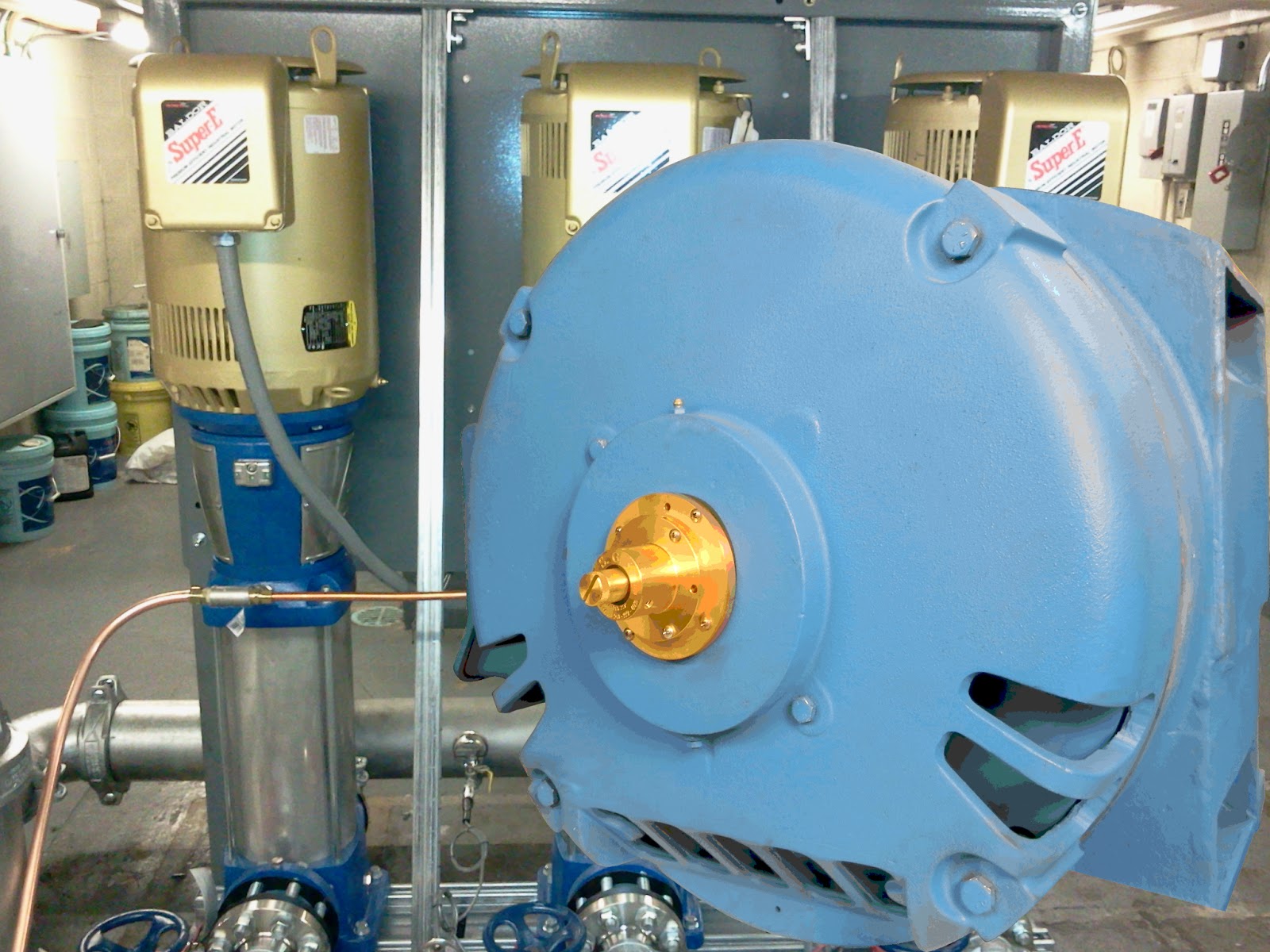

With SGS

- Motors run for decades without electrical bearing damage

- Downtime is eliminated

- You gain peace of mind knowing your operation is protected